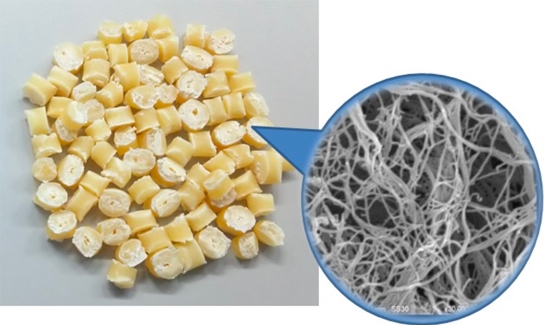

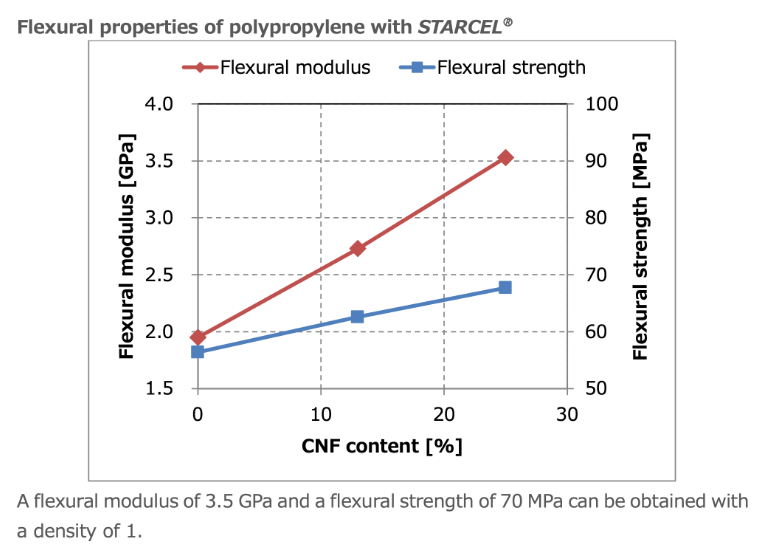

Cellulose nanofiber (CNF) is a nanofiber obtained by defibrillating cellulose to the nano-size and has superior features including low density, high strength, high elastic modulus and low thermal expansion.

CNF can be applied as reinforcing fibers for thermoplastic resins. CNF resin composite is expected to be applied to various fields such as automotive, home electric appliances and building materials.

STARCEL® series:CNF Resin Composite

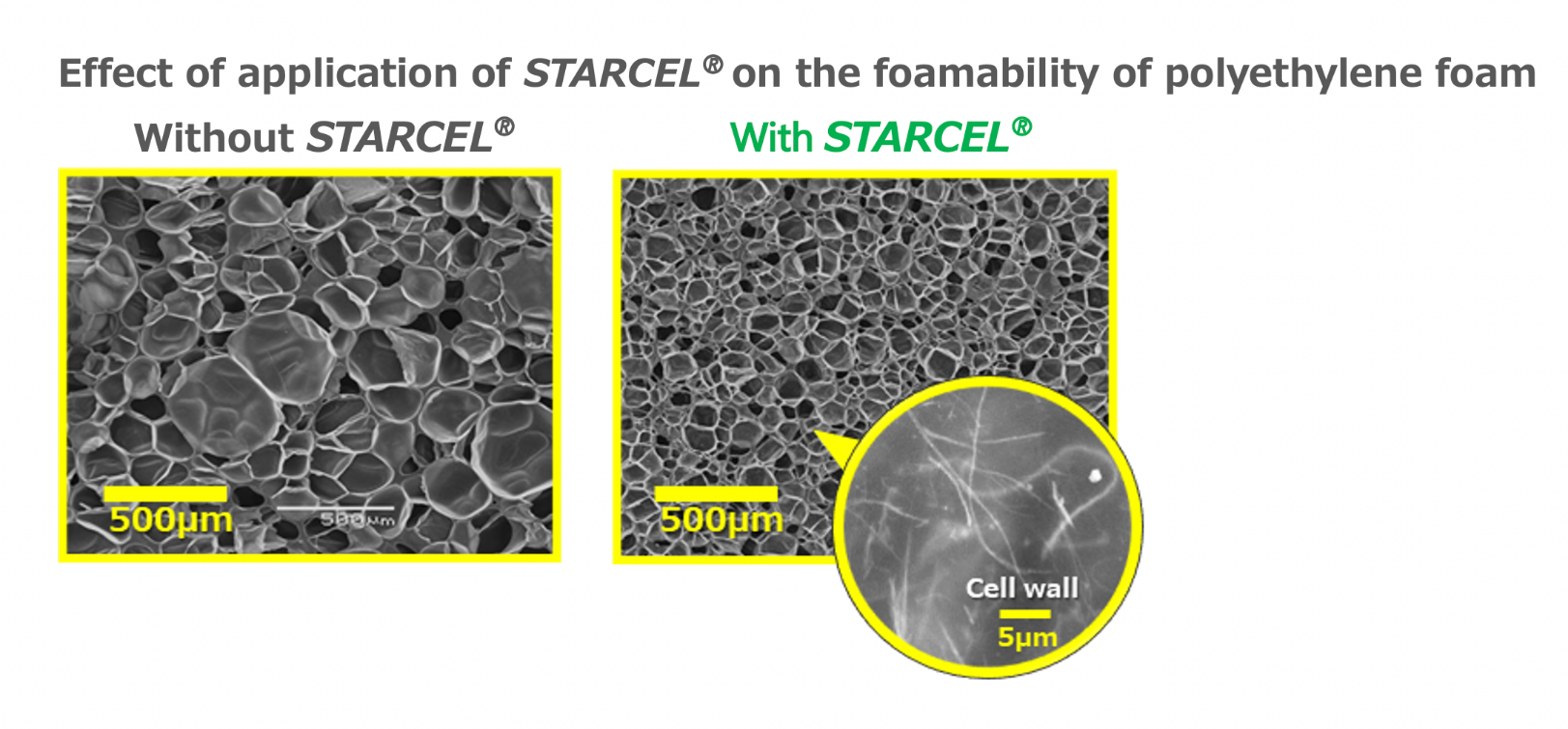

CNF suppresses expanding cell size and reinforces the bubble wall,

We are working with our clients to develop a variety of practical applications.

※For further information about STARCEL®, please contact us on our website.